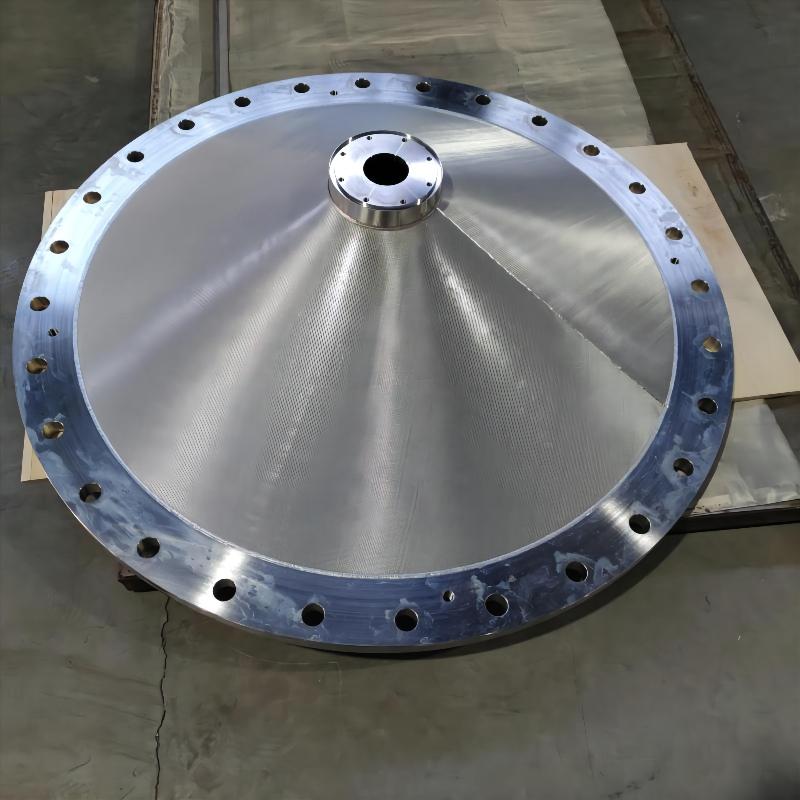

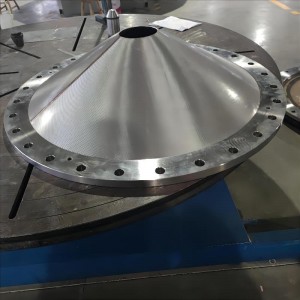

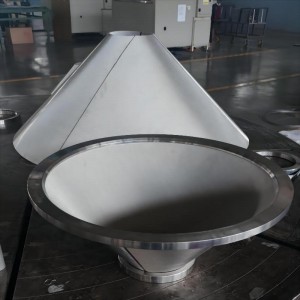

Ukwakheka

Izinto zokwakha

DIN 1.4404 / AIS 316L, DIN 1.4539 / Aisi 904L

I-Monel, Inxote, I-Duple Steel, Hastelloy Alloys

Ezinye izinto ezitholakala ngesicelo.

Hlunga FINGENT: 1 -100 microns

Ukucacisa

| Ukucaciswa -wamisa-ungqimba oluyisihlanu | ||||||||

| Ukufanisa | hlunga ubuwula | Ukwakheka | Ukujiya | Ububanzi | I-Air Permeability | Rp | Ubunzima | Ingcindezi ye-Bubble |

| μM | mm | % | (L / min / cm²) | N / cm | kg / ㎡ | (MmH₂O) | ||

| I-SSM-F-1 | 1 | 100 + 400x28000000 + 12 + 64 + 64/12 | 1.7 | 37 | I-1.82 | I-1080 | 8.4 | I-360-600 |

| I-SSM-F-2 | 2 | 100 + 325x2300 + 100 + 12/6/64 + 64/12 | 1.7 | 37 | I-2.36 | I-1080 | 8.4 | 300-590 |

| I-SSM-F-5 | 5 | 100 + 200x1400 + 100 + 12/64 + 64/12 | 1.7 | 37 | 2.42 | I-1080 | 8.4 | 260-550 |

| I-SSM-F-10 | 10 | 100 + 165x1400 + 100 + 12/64 + 64/12 | 1.7 | 37 | I-3.08 | I-1080 | 8.4 | 220-500 |

| I-SSM-F-15 | 15 | 100 + 165x1200 + 100 + 12/64 + 64/12 | 1.7 | 37 | 3.41 | I-1080 | 8.4 | 200-480 |

| I-SSM-F-20 | 20 | 100 + 165x800 + 100 + 12/64 + 64/12 | 1.7 | 37 | I-4.05 | I-1080 | 8.4 | 170-450 |

| I-SSM-F-25 | 25 | 100 + 165x600 + 100 + 12/64 + 64/12 | 1.7 | 37 | 6.12 | I-1080 | 8.4 | 150-410 |

| I-SSM-F-30 | 30 | 100 + 400 + 100 + 12/ 64 + 64/12 | 1.7 | 37 | 6.7 | I-1080 | 8.4 | 120-390 |

| I-SSM-F-40 | 40 | 100 + 325 + 100 + 12/ 64 + 64/12 | 1.7 | 37 | I-6.86 | I-1080 | 8.4 | 100-350 |

| I-SSM-F-50 | 50 | 100 + 250 + 100 + 12/ 64 + 64/12 | 1.7 | 37 | 8.41 | I-1080 | 8.4 | 90-300 |

| I-SSM-F-75 | 75 | 100 + 200 + 100 + 12/ 64 + 64/12 | 1.7 | 37 | 8.7 | I-1080 | 8.4 | 80-250 |

| I-SSM-F-100 | 100 | 100 + 150 + 100 + 12/ 64 + 64/12 | 1.7 | 37 | 9.1 | I-1080 | 8.4 | 70-190 |

Izici zensimbi engenasici

1. I-Filtration iqinile futhi iyunifomu: ivikelwe yizendlalelo eziphezulu nezingaphansi ze-wire mesh, ehlanganiswe nenqubo eqinile yokuphazamiseka nokuqina, futhi kungafinyelela ukusebenza kwe-Filtration okukhona kuyo yonke inqubo yokuhlunga kanye ne-automation.

2. Amandla amahle: asekelwa yisendlalelo sokuqinisa kanye nongqimba wokusekelwa, inamandla aphezulu wemishini namandla acindezelayo.

3. Ukucutshungulwa okulula: Kulungele ukusika, ukugoba, ukunyathela, ukunwebeka, ukushiswa kanye nezinye izindlela zokucubungula, okulula ukuyisebenzisa.

I-4. Ububanzi bokukhethwa kwezinto ezibonakalayo: I-316L, 304, 321, njll. Ingasetshenziswa.

I-5

I-6. Ibanga elibanzi lezindawo ezisetshenziswayo

7. Kulula ukuhlanza: ngenxa yokwakheka okuhleliwe, usayizi we-pore ofanayo, iziteshi ezibushelelezi nezilula kanye nokuhlanza amanzi aphezulu, ukuncibilika kwamanzi okukhohlakele, ukuncibilika kwamanzi, kungasetshenziswa kaninginingi, izici zokuphila ezinde.

I-Stainless Steel Conical Contered Mesh Filter Element Ibanga lesicelo

1..

2. I-High-Pressure Medium Filtration; Ukuhlukaniswa kwesihlabathi samafutha;

3. Imishini, imikhumbi, kaphethiloli, uwoyela wokuthambisa, uwoyela wokuqala we-hydraulic;

4. Icubungula ukugcotshwa kwamasethi aphelele wemishini yamakhemikhali embonini yamakhemikhali;

I-5

Izinja

Imibhede efihlekile, izihlungi ze-nutsche, amasentimitha ama-centrifugs, a aferation of silos, izinhlelo zokusebenza nge-biotechnology.