Ukwakheka

Izinto zokwakha

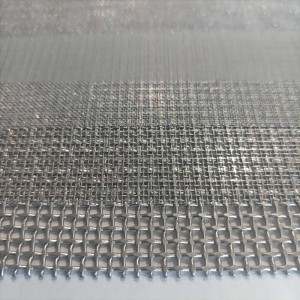

DIN 1.4404 / AIS 316L, DIN 1.4539 / Aisi 904L

I-Monel, Inxote, I-Duple Steel, Hastelloy Alloys

Ezinye izinto ezitholakala ngesicelo.

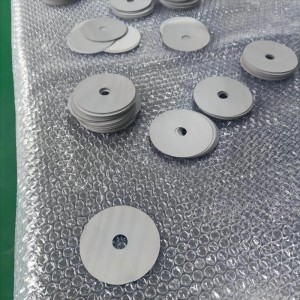

Hlunga FINGENSE: 1 -200 microns

Ukucacisa

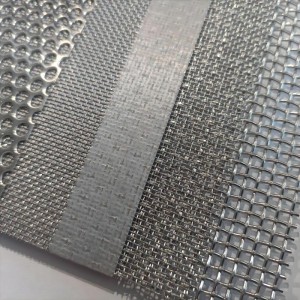

| Ukucaciswa - ukubhoboza ipuleti i-wire mesh | ||||

| Ukufanisa | hlunga ubuwula | Ukwakheka | Ukujiya | Ububanzi |

| μM | mm | % | ||

| I-SSM-P-1.5T | 2-100 | Ungqimba wokuhlunga + 60 + 30 + φ00x5px1.0t | 1.5 | 57 |

| SSM-P-2.0t | 2-100 | I-30 + Uhlu lokuhlunga + 30 + φ5x7px1.5t | 2 | 50 |

| I-SSM-P-2.5T | 20-100 | I-Fitter ungqimba + 60 + 30 + φ00x5px1.5t | 2,5 | 35 |

| SSM-P-3.0t | 2-200 | I-60 Filter ungqimba + 60 + 20 + φ2x8p.0t | 3 | 35 |

| SSM-P-4.0t | 2-200 | + Ukuhlunga ungqimba + 30 20 + 20 + φ9xx2.5t | 4 | 50 |

| SSM-P-5.0t | 2-200 | + Ukuhlunga + 30 + 20 + 16 + 10 + φ810px3.0t | 5 | 55 |

| SSM-P-6. 6.0t | 2-20 | + Ukuhlunga + 30 + 20 + 16 + 10 + φ8xx4.0t | 6 | 50 |

| SSM-P-7.00t | 2-20 | + Ukuhlunga + 30 + 20 + 16 + 10 + φ810px5.0t | 7 | 50 |

| I-SSM-P-8.0t | 2-20 | + Ukuhlunga + 30 + 20 + 16 + 10 + φ8xx6.0t | 8 | 50 |

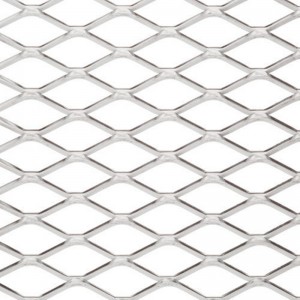

| Ubukhulu bepuleti lokubhoboza kanye nokwakheka kwe-wire mesh kungenziwa ngokwezifiso ngokuya ngezidingo zomsebenzisi. | ||||

Izimo, uma zisetshenziswa kuhluzo olusebenzayo lokuhlanza imidwebo yokuwasha, isakhiwo sepuleti yokuhlunga singaba ungqimba olujwayelekile nepuleti elihlanganisiwe.

Leyo yingqimba yokuhlunga eyi-100 + 100 + 12/64 + 64/12 + 4.0t (noma enye inqwaba yepuleti yokubhoboza)

Ubukhulu bepuleti lokubhoboza buye buye kuncike ekufuneni kwakho kwengcindezi

Lo mkhiqizo ulungele izindawo eziphakeme zokucindezela noma ingcindezi ephezulu yokufunwa emuva, ukuxazulula ngempumelelo ukukhiqizwa okuqhubekayo kwemboni yezemithi neyekhemikhali kanye nezidingo zokukhiqiza eziyinyumba.

Izinja

Ukudla nesiphuzo, ukwelashwa kwamanzi, ukuvusa uthuli, ekhemisi, amakhemikhali, i-polymer, njll.

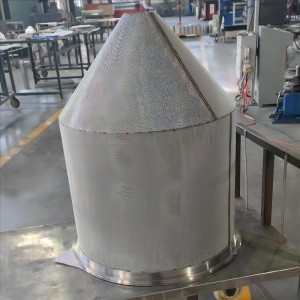

Ama-cartridge e-cartidges ane-conical aqanjwe ngesimo sawo. Kungokwendlela yokuhlunga elula kunazo zonke yochungechunge lokuhlunga lwamapayipi. Kungasusa ukungcola okukhulu koketshezi lapho kufakwe epayipini, ukuze imishini nemishini (kufaka phakathi ama-compressors, amaphampu, njll.) Futhi izinsimbi zingasebenza futhi zithola inqubo ezinzile. Indima yokuqinisekisa ukukhiqizwa okuphephile. Lapho uketshezi lungena kwi-cartridge yokuhlunga ngesikrini sokuhlunga somcaciso othile, ukungcola kuvinjelwe, futhi i-filtrate ehlanzekile ikhishwa kusuka endaweni yokuhlunga. Lapho ukuhlanza kuyadingeka, vele ukhiphe i-cartridge yokuhlunga ebonakalayo bese uyifaka kabusha ngemuva kokwelashwa. Yebo, ngakho-ke, kulula kakhulu ukusebenzisa nokugcina. Izici zokuhlunga zesikhashana: Isetshenziswa ikakhulukazi ngaphambi kokuqala kwepayipi lemishini, elifakwe phakathi kwamaphaneli amabili epayipini, futhi asuse ukungcola epayipini; Imishini ilula, ithembekile, futhi inezinhlobonhlobo zezicelo.