Isakhiwo

Izinto zokwakha

I-DIN 1.4404/AISI 316L, DIN 1.4539/AISI 904L

Monel, Inconel, Duples steel, Hastelloy alloys

Ezinye izinto ezitholakalayo uma uzicela.

Ukuqina kwesihlungi: 1 -200 microns

Imininingwane

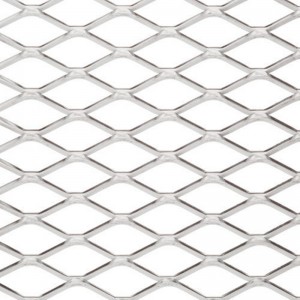

| Ukucaciswa - Punching plate sintered wire mesh | ||||

| Incazelo | isihlungi esihle | Isakhiwo | Ubukhulu | I-Porosity |

| μm | mm | % | ||

| I-SSM-P-1.5T | 2-100 | Isendlalelo sesihlungi esingu-60+60+30+Φ4x5px1.0T | 1.5 | 57 |

| I-SSM-P-2.0T | 2-100 | Isendlalelo sesihlungi esingu-30+30+Φ5x7px1.5T | 2 | 50 |

| I-SSM-P-2.5T | 20-100 | Isendlalelo sesihlungi esingu-60+60+30+Φ4x5px1.5T | 2.5 | 35 |

| I-SSM-P-3.0T | 2-200 | Isendlalelo sesihlungi esingu-60+60+20+Φ6x8px2.0T | 3 | 35 |

| I-SSM-P-4.0T | 2-200 | Isendlalelo sesihlungi esingu-30+30+20+Φ8x10px2.5T | 4 | 50 |

| I-SSM-P-5.0T | 2-200 | 30+isihlungi+30+20+16+10+Φ8x10px3.0T | 5 | 55 |

| I-SSM-P-6.0T | 2-250 | 30+isihlungi+30+20+16+10+Φ8x10px4.0T | 6 | 50 |

| I-SSM-P-7.0T | 2-250 | 30+isihlungi+30+20+16+10+Φ8x10px5.0T | 7 | 50 |

| I-SSM-P-8.0T | 2-250 | 30+isihlungi+30+20+16+10+Φ8x10px6.0T | 8 | 50 |

| Ubukhulu bepuleti lokubhoboza kanye nesakhiwo se-wire mesh kungenziwa ngokwezifiso ngokuya ngezidingo zomsebenzisi. | ||||

Ukuphawula, uma isetshenziswa ku-Multifunctional filter washing dryers, isakhiwo sepuleti lesihlungi singaba izendlalelo ezinhlanu ezijwayelekile kanye nepuleti lokubhoboza elihlanganiswe ndawonye.

Lokho ungqimba lwesihlungi esingu-100++100+12/64+64/12+4.0T(noma Olunye ugqinsi lokubhoboza ipuleti)

Ukuqina kwepuleti lokubhoboza nakho kuncike ekufuneni kwakho ingcindezi

Lo mkhiqizo ulungele izindawo ezinengcindezi ephezulu noma isidingo se-backwashing ephezulu, ukuxazulula ngempumelelo ukukhiqizwa okuqhubekayo kwemboni yezemithi namakhemikhali kanye nokuwashwa kabusha okuku-inthanethi, izidingo zokukhiqiza eziyinyumba.

Izinhlelo zokusebenza

Ukudla&isiphuzo, ukulungiswa kwamanzi, ukususa uthuli, ikhemisi, amakhemikhali, i-polymer, njll.

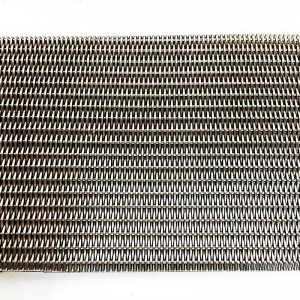

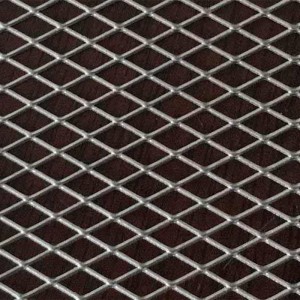

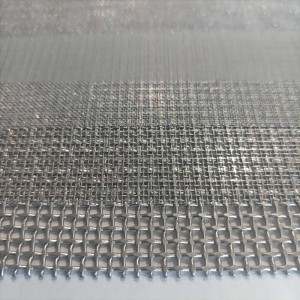

Isici sokuhlunga esijwayelekile sezendlalelo ezinhlanu se-sintered mesh sisongwa ngokuyinhloko yisihlungi esijwayelekile sezendlalelo ezinhlanu ze-sintered mesh.I-wire mesh ejwayelekile enezendlalelo ezinhlanu yenziwe ngezandlalelo ezinhlanu zensimbi engagqwali enezikhala ezibekwe phezulu kanye ne-vacuum sintered.Isici sokuhlunga esenziwe nge-standard five-layer sintered mesh sinezici zokumelana nokugqwala okuqinile, ukungena kahle, amandla aphezulu, ukuhlanzwa okulula nokuhlanza ingemuva, ukunemba kokuhlunga okufanayo, okokuhlunga okuhlanzekile nokuhlanzekile, kanye ne-wire mesh engachithi.

Amameshi wesendlalelo ngasinye sesici sesihlungi se-sintered mesh ayahlanganiswa ukuze akhe isihlungi esifanayo nesakhiwo esikahle, okwenza into ebalulekile ibe nezinzuzo ezingenakuqhathaniswa nemeshi yensimbi evamile, njengamandla aphezulu, ukuqina okuhle, kanye nemeshi.ukuqina komumo njll. Ngenxa yokumadanisa okunengqondo nokuklama kosayizi wembotshana, ukungeneka kanye nezici zamandla zezinto ezibonakalayo, inokunemba okuhle kakhulu kokuhlunga, ukumelana nokuhlunga, amandla emishini, ukumelana nokugqoka, ukumelana nokushisa kanye nokucutshungulwa, kanye nokusebenza okuphelele kungcono. .Iphakeme kunezinye izinhlobo zezinto zokuhlunga.

1. Izici zomkhiqizo:

I-1) I-mesh enezingqimba ezinhlanu ze-sintered yakhiwe ungqimba oluvikelayo, isendlalelo sokuhlunga, isendlalelo sokuhlakazeka kanye nezingqimba ezimbili zamathambo;

2) Amandla aphezulu: ngemva kokucwilisa i-mesh yocingo enezingqimba ezinhlanu, inamandla amakhulu omshini namandla okucindezela;

I-3) Ukunemba okuphezulu: Ingasebenzisa ukusebenza kokuhlunga kwendawo efanayo kusayizi wezinhlayiyana zokuhlunga we-1 kuya ku-200um;

4) Ukumelana nokushisa: Ingasetshenziselwa ukuhlunga okuqhubekayo kusuka ku--200 degrees kuya ku-650 degrees;

I-5) Ukuhlanzeka: Ngenxa yesakhiwo sokuhlunga okungaphezulu esinomphumela ongcono wokuhlanza ophikisanayo, ukuhlanza kulula.

I-6) Inokungena kahle namandla aphezulu, asikho isidingo sokwengeza isakhiwo sokusekela, akukho mpahla ewayo evamile, ukumelana nokugqwala okuqinile, ukuhlanza kulula futhi akulula ukulimaza.

2.Inhloso enkulu:

1) Isetshenziswa njengento yokupholisa ehlakazekile endaweni yokushisa ephezulu;

2) Isetshenziselwa ukusatshalaliswa kwegesi, i-orifice plate impahla yombhede owenziwe uketshezi;

3) Ngokunemba okuphezulu, okunokwethenjelwa okuphezulu kwesihlungi sokushisa okuphezulu;

4) Ukuze uthole isihlungi samafutha e-backwash aphezulu

5) Isetshenziselwa ukuhlunga i-polyester, imikhiqizo kawoyela, imithi, ukudla nesiphuzo, imikhiqizo ye-fiber yamakhemikhali namakhemikhali, kanye nokwelashwa kwamanzi nokuhlunga kwegesi.

Qaphela: Ubukhulu bungenziwa ngokuya ngezidingo zamakhasimende.Ingacutshungulwa ibe yi-tubular, i-disc, ikhandlela nezinye izakhi zokuhlunga.