Isakhiwo

Izinto zokwakha

I-DIN 1.4404/AISI 316L, DIN 1.4539/AISI 904L

Monel, Inconel, Duples steel, Hastelloy alloys

Ezinye izinto ezitholakalayo uma uzicela.

Ukuqina kwesihlungi: 1 -200 microns

Imininingwane

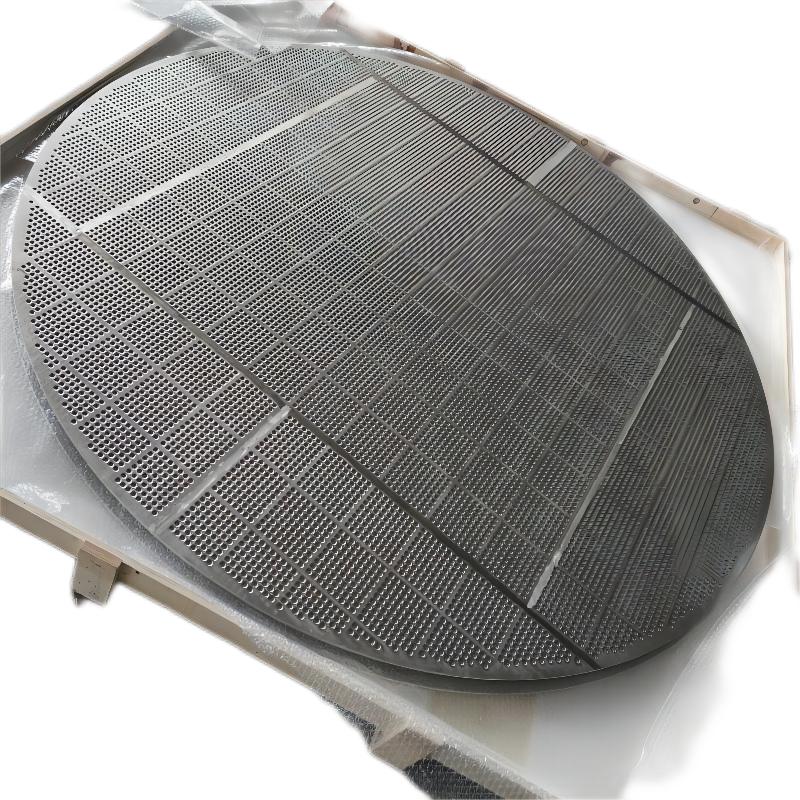

| Ukucaciswa - Punching plate sintered wire mesh | ||||

| Incazelo | isihlungi esihle | Isakhiwo | Ubukhulu | I-Porosity |

| μm | mm | % | ||

| I-SSM-P-1.5T | 2-100 | Isendlalelo sesihlungi esingu-60+60+30+Φ4x5px1.0T | 1.5 | 57 |

| I-SSM-P-2.0T | 2-100 | Isendlalelo sesihlungi esingu-30+30+Φ5x7px1.5T | 2 | 50 |

| I-SSM-P-2.5T | 20-100 | Isendlalelo sesihlungi esingu-60+60+30+Φ4x5px1.5T | 2.5 | 35 |

| I-SSM-P-3.0T | 2-200 | Isendlalelo sesihlungi esingu-60+60+20+Φ6x8px2.0T | 3 | 35 |

| I-SSM-P-4.0T | 2-200 | Isendlalelo sesihlungi esingu-30+30+20+Φ8x10px2.5T | 4 | 50 |

| I-SSM-P-5.0T | 2-200 | 30+isihlungi+30+20+16+10+Φ8x10px3.0T | 5 | 55 |

| I-SSM-P-6.0T | 2-250 | 30+isihlungi+30+20+16+10+Φ8x10px4.0T | 6 | 50 |

| I-SSM-P-7.0T | 2-250 | 30+isihlungi+30+20+16+10+Φ8x10px5.0T | 7 | 50 |

| I-SSM-P-8.0T | 2-250 | 30+isihlungi+30+20+16+10+Φ8x10px6.0T | 8 | 50 |

| Ubukhulu bepuleti lokubhoboza kanye nesakhiwo se-wire mesh kungenziwa ngokwezifiso ngokuya ngezidingo zomsebenzisi. | ||||

Ukuphawula, uma isetshenziswa ku-Multifunctional filter washing dryers, isakhiwo sepuleti lesihlungi singaba izendlalelo ezinhlanu ezijwayelekile kanye nepuleti lokubhoboza elihlanganiswe ndawonye.

Lokho ungqimba lwesihlungi esingu-100++100+12/64+64/12+4.0T(noma Olunye ugqinsi lokubhoboza ipuleti)

Ukuqina kwepuleti lokubhoboza nakho kuncike ekufuneni kwakho ingcindezi.

Lo mkhiqizo ulungele izindawo ezinengcindezi ephezulu noma isidingo se-backwashing ephezulu, ukuxazulula ngempumelelo ukukhiqizwa okuqhubekayo kwemboni yezemithi namakhemikhali kanye nokuwashwa kabusha okuku-inthanethi, izidingo zokukhiqiza eziyinyumba.

Izinhlelo zokusebenza

Ukudla&isiphuzo, ukulungiswa kwamanzi, ukususa uthuli, ikhemisi, amakhemikhali, i-polymer, njll.

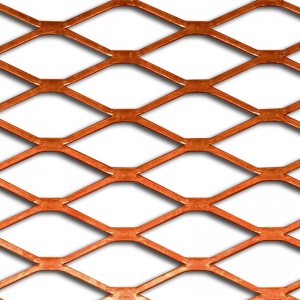

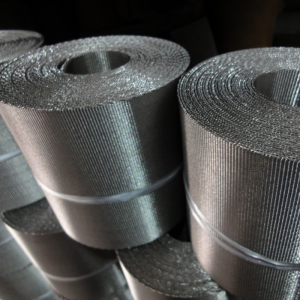

Ipuleti elinezimbobo ezinezikhala ezisikiwe wuhlobo lwe-sintered mesh efaka ipuleti elinezimbotshana kanye nesisekelo esiyisicaba esilukiwe semeshi ndawonye.Ipuleti lokubhoboza lingakhethwa ngokuqina okuhlukene ngokwezidingo, futhi inetha lokweluka elingenalutho lingaba ungqimba olulodwa noma ngaphezulu.Ngenxa yepuleti lokubhoboza njengosekelo, i-mesh eyinhlanganisela inamandla acindezelayo aphezulu namandla okusebenza.I-sintering yalokhu kokubili akugcini nje ngokuba nomoya omuhle wokungena kwe-mesh elukiweyo eyisicaba, kodwa futhi inamandla omshini wepuleti elinezimbotshana.Ingacutshungulwa ibe yizihlungi ze-cylindrical, disc, sheet kanye ne-cone, ezisetshenziswa kabanzi ekwelapheni amanzi, isiphuzo, ukudla, i-metallurgy, izimboni zamakhemikhali nezemithi, njll.

Izici ze-perforated plate sintered mesh:

(1) Ukuqina okuhle namandla aphezulu emishini.Ngenxa yokusekelwa kwepuleti lokubhoboza, inamandla aphakeme kakhulu emishini namandla acindezelayo phakathi kwamameshi ane-sintered;

(2) Ukunemba okuphezulu kokuhlunga, ububanzi bokunemba kokuhlunga ngu-1μ-100μ, futhi linokusebenza okuthembekile kokuhlunga;

(3) Kulula ukuhlanza, isihlungi esingaphezulu siyamukelwa, sifaneleka ngokukhethekile ukugeza emuva;

(4) Ayigogeki kalula, ukuma kwemeshi kulungisiwe, ubukhulu begebe buyiyunifomu, futhi ayikho imbobo eyimpumputhe.

(5) Ukumelana nokugqwala, ukumelana nokushisa okuphezulu, kungamelana nokushisa okuphezulu kwama-480 ℃.

Ukusetshenziswa kwe-mesh ye-perforated plate sintered:

(1) Izinto ezisetshenziselwa ukupholisa okuhlakazayo endaweni yokushisa ephezulu kakhulu.

(2) Ukuze kusetshenziswe ukufana kwegesi embonini yempushana, amapuleti aguquliwe embonini yensimbi.

(3) Okubalulekile kwepuleti le-Orifice lombhede omanzi wokusatshalaliswa kwegesi.

(4) Isetshenziswa ekuqhumeni komjovo wesithando somlilo ocijile ukugeleza kwamalahle kanye nesistimu yokudlulisa isigaba esiminyene.

(5) Ukuhlunga, ukuwashwa nokomiswa kwezinto embonini yezemithi.

(6) I-Catalyst support grille.

(7) Isetshenziselwa ukuhlunga i-polyester, uwoyela, ukudla nesiphuzo, imikhiqizo ye-fiber yamakhemikhali, kanye nokuhlanza amanzi kanye nokuhlunga kwegesi.