Ukwakheka

Izinto zokwakha

DIN 1.4404 / AIS 316L, DIN 1.4539 / Aisi 904L

I-Monel, Inxote, I-Duple Steel, Hastelloy Alloys

Ezinye izinto ezitholakala ngesicelo.

Hlunga FINGENSE: 1 -200 microns

Ukucacisa

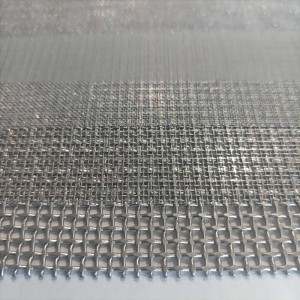

| Ukucaciswa - ukubhoboza ipuleti i-wire mesh | ||||

| Ukufanisa | hlunga ubuwula | Ukwakheka | Ukujiya | Ububanzi |

| μM | mm | % | ||

| I-SSM-P-1.5T | 2-100 | Ungqimba wokuhlunga + 60 + 30 + φ00x5px1.0t | 1.5 | 57 |

| SSM-P-2.0t | 2-100 | I-30 + Uhlu lokuhlunga + 30 + φ5x7px1.5t | 2 | 50 |

| I-SSM-P-2.5T | 20-100 | I-Fitter ungqimba + 60 + 30 + φ00x5px1.5t | 2,5 | 35 |

| SSM-P-3.0t | 2-200 | I-60 Filter ungqimba + 60 + 20 + φ2x8p.0t | 3 | 35 |

| SSM-P-4.0t | 2-200 | + Ukuhlunga ungqimba + 30 20 + 20 + φ9xx2.5t | 4 | 50 |

| SSM-P-5.0t | 2-200 | + Ukuhlunga + 30 + 20 + 16 + 10 + φ810px3.0t | 5 | 55 |

| SSM-P-6. 6.0t | 2-20 | + Ukuhlunga + 30 + 20 + 16 + 10 + φ8xx4.0t | 6 | 50 |

| SSM-P-7.00t | 2-20 | + Ukuhlunga + 30 + 20 + 16 + 10 + φ810px5.0t | 7 | 50 |

| I-SSM-P-8.0t | 2-20 | + Ukuhlunga + 30 + 20 + 16 + 10 + φ8xx6.0t | 8 | 50 |

| Ubukhulu bepuleti lokubhoboza kanye nokwakheka kwe-wire mesh kungenziwa ngokwezifiso ngokuya ngezidingo zomsebenzisi. | ||||

Izimo, uma zisetshenziswa kuhluzo olusebenzayo lokuhlanza imidwebo yokuwasha, isakhiwo sepuleti yokuhlunga singaba ungqimba olujwayelekile nepuleti elihlanganisiwe.

Leyo yingqimba yokuhlunga eyi-100 + 100 + 12/64 + 64/12 + 4.0t (noma enye inqwaba yepuleti yokubhoboza)

Ubukhulu bepuleti lokushaya buye buye kuncike ekufuneni kwakho kwengcindezi.

Lo mkhiqizo ulungele izindawo eziphakeme zokucindezela noma ingcindezi ephezulu yokufunwa emuva, ukuxazulula ngempumelelo ukukhiqizwa okuqhubekayo kwemboni yezemithi neyekhemikhali kanye nezidingo zokukhiqiza eziyinyumba.

Izinja

Ukudla nesiphuzo, ukwelashwa kwamanzi, ukuvusa uthuli, ekhemisi, amakhemikhali, i-polymer, njll.

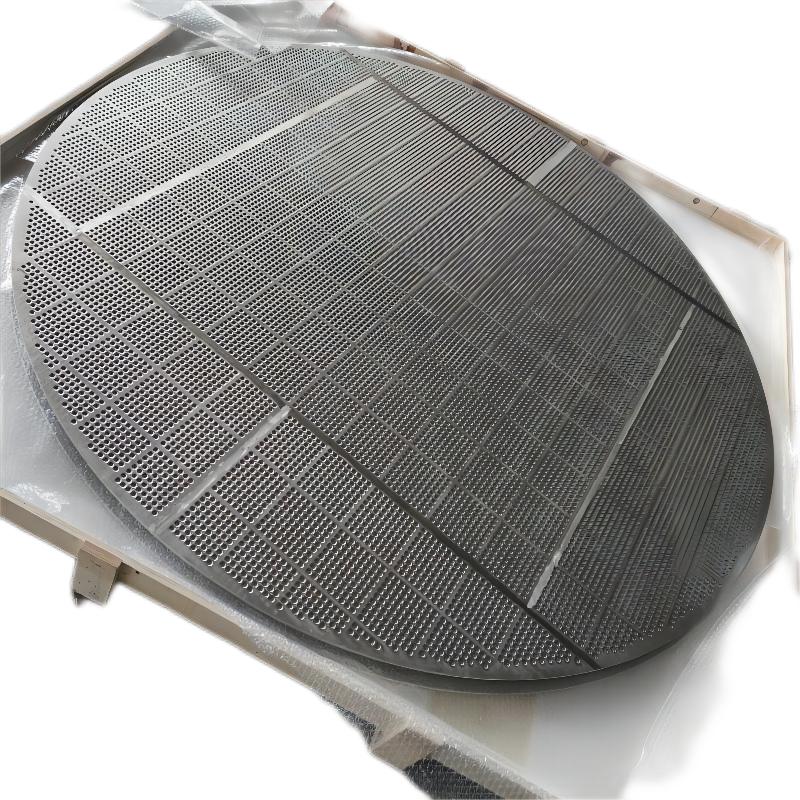

Ipuleti elihlanganisiwe le-mesh luhlobo lwe-mesh olunesono oluhlalisana ipuleti ye-porous kanye ne-bar flat flat mesh ndawonye. Ipuleti lokubhoboza lingakhethwa ngobukhulu obuhlukile ngokuya ngezidingo, futhi inetha elivikeleke elisobala lingaba yizendlalelo esisodwa noma eziningi. Ngenxa yepuleti yokubhoboza njengokusekelwa, i-composite mesh inamandla amakhulu acindezelwe namandla okusebenza. Isono salaba bobabili agcineli nje kuphela lapho kuvela khona umoya omuhle we-mesh elukiwe, kodwa futhi namandla okusebenza epuletini ye-porous. Ingacutshungulwa ibe yi-cylindrical, disc, eshidi kanye nezihlungi zesigaxa, ezisetshenziswe kabanzi ekuphumeni kwamanzi, isiphuzo, ukudla, izimboni ze-metallurgy, njll.

Ipuleti elihlanganisiwe le-mesh izici:

(1) Amandla amahle namandla aphezulu emishini. Ngenxa yokwesekwa kwepuleti lokubhoboza, linamandla aphakeme kakhulu emishini namandla acindezelayo phakathi kwamaMeshes anama-mince;

.

(3) Kulula ukuhlanza, ukuhlunga okungaphezulu kwamukelwa, ikakhulukazi kufanelekile ukuba bahlabe emuva;

(4) Akukonakaliswa kalula, ukwakheka kwe-mesh kulungisiwe, usayizi wegebe ufana umfaniswano, futhi akukho umgodi oyimpumputhe.

(5) Ukumelana nokugqwala, ukumelana okushisa okuphezulu, kungamelana nokushisa okuphezulu kwe-480 ℃.

Ipuleti elihlanganisiwe le-mesh lisebenzisa:

(1) Izinto ezisetshenziselwa ukupholisa okuhluphekayo ezindaweni eziphakeme kakhulu zokushisa.

(2) Ukusetshenziswa kwegesi ethakathi embonini ye-powder, amapuleti afihlekile embonini yensimbi.

.

.

(5) I-FILTRATION, ukugeza kanye nokumiswa kwezinto zokwakha embonini yezemithi.

(6) I-Catalyst Support Greele.

(7) Isetshenziselwa ukugcwala kwe-polyester, uwoyela, ukudla kanye nesiphuzo, imikhiqizo yamakhemikhali fiber, kanye nokulashwa kwamanzi kanye nokuhlunga kwegesi.